2018 nowy design vietnam a2 dtg płaski t-shirt drukarka do drukowania parrel

Specyfikacje

Usage:Card Printer, Cloths Printer, T shirt printer, garment printer, textile printer

Typ płyty: Płaska drukarka

Stan: nowy

Dimensions(L*W*H):120cm*90cm*60cm

Waga: 100 kg

Automatyczna klasa: półautomatyczna

Napięcie: 220V / 110V

Głowica drukująca: głowica drukująca DX5 / DX7

Ink type:dye aublimation ink, water based pigment inks

Ink colors:Cyan, Magenta, Yellow, Black, White.

Max resolution:1440*1440dpi

Application:T-shirt printing, textile printing, garment printing,etc

printing size:420mm*900mm

Accessories for option:heat press, T-shirt frame, T-shirt inks, etc

Warranty:12 months

Delivery:7-10 days aftr deposit/payment

Payment method:T/T, West Union, Ali Trading Assurance, LC, etc.

Typ: drukarka cyfrowa

Obsługa posprzedażna: Inżynierowie są dostępni do obsługi maszyn za granicą

T-shirt samples

This model A3 size flatbed T-shirt printer can print on both White and dark color T-shirts. It can print C,M,Y,K+WWWW color inks.

Printing process

For starting T-shirt printing business, you need the T-shirt printer, heat press machine, T-shirt tray and special textile inks for T-shirts.

1, The heat press machine is for treating the T-shirt or garment plain before printing. You just need to heat the T-shirt for 45s.

2, The T-shirt tray is for holding the T-shirt edges while printing.

3, The textile inks for T-shirts printing is water based type, it can be absorbed by the textile, so the prints will be washable and no ink fade. The print feels very soft and comfortable, though it's not as bright/glossy as heat tranfer prints.

4, More importantly, the special textile inks for T-shirt is no harm to body skins.

Specyfikacja

| er Model | A2 ATZ-D4880T digital T-shirt flatbed printer |

| Metoda drukowania | Micro Piezo Technology |

| Max Print Thickness | 13cm |

| Max flatbed size | 420 mm * 900 mm |

| Rozdzielczość wydruku | 1440 * 1440 dpi |

| Jakość wydruku | Prawdziwa jakość fotograficzna |

| Kierunek drukowania | Inteligentny tryb drukowania dwukierunkowego |

| Szybkość drukowania | 720 dpi 25 seconds/A4 size |

| 1440 dpi 50 seconds/A4 sizes | |

| 2880 dpi 110 seconds/A4 sizes | |

| Metoda drukowania | Continuous Production |

| Max Media weight | 20 KGs NET. |

| System operacyjny | Windows XP/ME/Vista/Win7/MAC |

| Berło | Double USB port |

| Języki | English, Chinese |

| Kolory farb | Dual C, M, Y, K / C, M, Y, K, W, W, W, W |

| Rodzaj atramentu | Water based ink for phone case direct printing |

| System atramentowy | CISS zbudowany wewnątrz |

| Zasilanie tuszem | 250 ml/bottle |

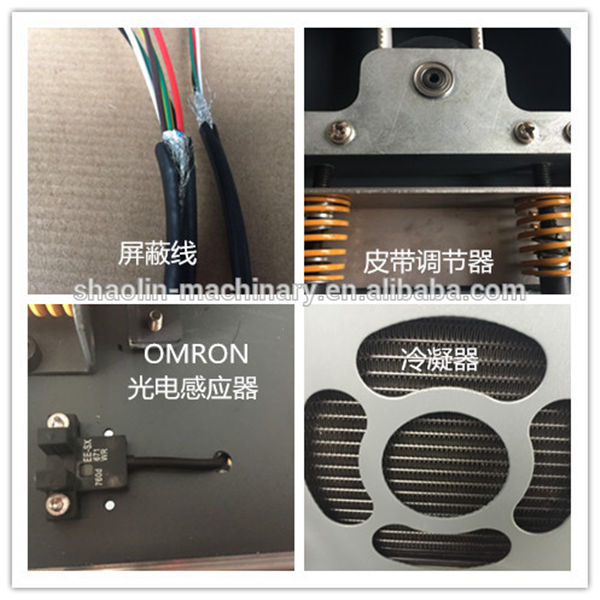

| Regulacja wysokości | Automatyczny z czujnikiem |

| Moc napędowa | 110 V/ 220 V |

| Power consumption | 750 W/ Hour |

| Zużycie atramentu | 7 ML/SQM |

| Środowisko pracy | 10-35 degrees |

| Oprogramowanie | Photoshop, CorelDraw, Illustrator, WER RIP |

| Package type | Timber Package with fumigation |

| Package size L*W*H | 1200mm*900mm*600mm |

| Waga netto | 80 KGs |

| Waga brutto | 100 KGs |

| System podawania mediów | podręcznik |

| Uszczelka | Timber with fumigation certificate. |

| Special remarks | Customized service is available. |

Printer users

Printer packing

The T-shirt printer is packed with standard exporting wood box.

And the packing size is 1.2m*0.9m*0.6m, 100KG.

This model T-shirt printer is fitable for delivery by both Ocean ships or Air cargo.

RFQ

1. What materials we can print on ?

For cotton T-shirts, both White and Color T-shirts,Cotton bags,cotton cloth decorations and so on.

2. What's the production capacity / printing speed?

It takes about 60 sec.for printing A4 size in mass printing mode.And the printing resolution and speed is adjustable per your business requests.

3. Jak przenosić maszyny?

T-shirt printers belong to precise instrument, when you move them, please turn off all power, remove the cartridges and waste cartridge, keep other parts on the printer, and handle with care, keep shaking and heavy goods away from the printer.

4. How to make 3D real vision?

Design the image file with 3D vision,and print with ATZ 3D printing technology.

5. How to maintain the print head?

Trun off power, move the printhead to the initial position, check if the printhead and cap top is in the same line.

Do one time cleaning action, and print the test status.

If above operation still can't solve this problem, then disassembly the printhead, cleaning the printhead manually or use cleaning machine to clean the printhead.

If the status keep the same after above all operations, pls do feel free to contact with our technician for helps.

6. How to maintain the printer if stop the printing for several days?

If you stop printing works for more than 3 days, you must cleaning out all ink in the printhead, otherwise, the ink will be dry because the solvent volatilization, even cause irreversible damage for the nozzles of the printhead. Following is the solving methods:

6.1Turn off the power of the printer

6.2 Move the printhead to the cleaning position, put a corrosion resistant container below the printhead for filling the waste cleaning solution

6.3 Unplug the printhead from the ink damper, then using the special cleaning solution to cleaning the printhead by glass syringe, and do this some times, at last do not suction out all cleaning solution from the printhead, put enough cleaning solution in the inner of the pritnhead, because the printhead can keep the nozzles moisture.

Please put the printhead into the clean container and seal it.